3D printing is revolutionizing the way we create and manufacture objects. From toys to airplane parts, this technology has the potential to produce almost anything you can imagine. However, for many people, the process of 3D printing remains a mystery. In this article, we will get into the mechanics of 3D printing, breaking down the steps and techniques involved in creating a three-dimensional object from a digital file. This guide will provide you with a comprehensive understanding of how 3D printing works.

3D Printing Technology Definition

Also known as additive manufacturing, is a process of creating three-dimensional objects by adding successive layers of material until the desired shape is achieved. Technology has revolutionized the way we think about manufacturing, allowing for greater customization and quicker production times.

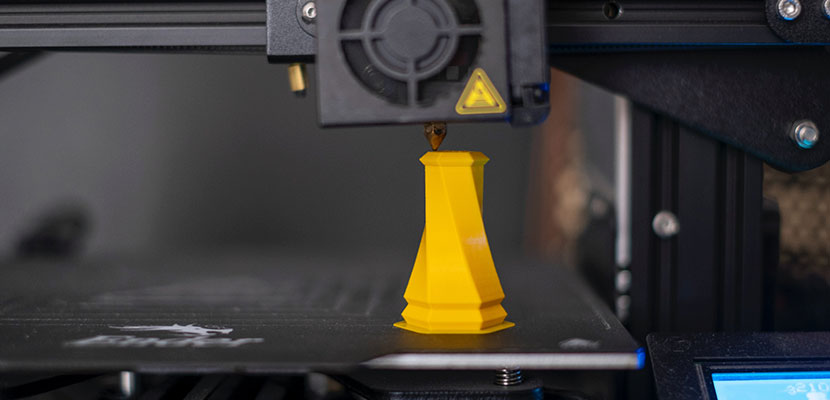

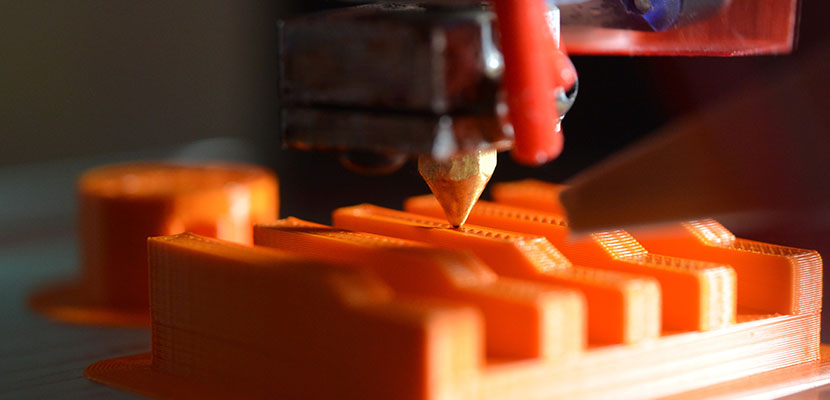

The basic principle of 3D printing is simple: a computer-aided design (CAD) file is used to guide the printer to build up an object layer by layer. The material used in 3D printing can vary, with common choices including plastics, metals, and even food. The material is typically melted or softened and extruded through a small nozzle, which deposits the material in precise locations according to the design file.

3D Printing Types

There are many different technologies for 3D printing, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Each of these technologies uses different methods to create objects, but the end result is the same: a three-dimensional object that can be used for a variety of purposes.

Fused deposition modeling is the most common type of 3D printing. In this method, a filament of plastic material is heated and extruded through a nozzle, which deposits the material in precise locations to build up the object layer by layer. FDM is popular because it is relatively cheap and easy to use, and it is capable of producing objects with a wide range of properties, from rigid to flexible.

Stereolithography uses a laser to cure a photosensitive resin, hardening it into a solid object. The resin is typically held in a vat, and the laser traces the desired shape onto the surface of the resin. Where the laser hits the resin, it hardens, allowing the printer to build up the object layer by layer. This method is capable of producing objects with a high level of detail and accuracy, but it can be more expensive than FDM and may not be suitable for all applications.

Selective laser sintering uses a laser to heat and fuse small particles of material, such as plastic or metal, into a solid object. The material is spread in a thin layer over a platform, and the laser selectively fuses the particles together in the desired pattern. The platform then drops slightly and another layer of material is added, and the process repeats until the object is complete. SLS is capable of producing strong, durable objects, but it can be more expensive and complex than other 3D printing technologies.

The Process of 3D Printing

Regardless of the specific technology used, the process of 3D printing follows a similar set of steps:

- Design: A 3D model is created using computer-aided design software, such as AutoCAD or Blender. The design must be saved as a specific file type, such as .stl or .obj, in order for the 3D printer to read it.

- Slicing: The 3D model is "sliced" into individual layers, which will be used by the printer to build the object. The slicing process determines the direction, speed, and temperature of the printer, as well as other factors such as the amount of material used.

- Printing: The 3D printer reads the sliced file and begins building the object layer by layer, following the instructions provided by the slicing software. Depending on the size and complexity of the object, the printing process can take anywhere from a few minutes to several hours.

- Post-processing: Once the object is complete, it may require additional steps such as sanding, painting, or polishing to achieve the desired final result.

What are the Advantages of the 3D Printing Technology?

The most notable advantage, it allows for greater customization and faster production times. With 3D printing, designers and manufacturers can create unique, one-of-a-kind objects that would be difficult or impossible to produce using traditional manufacturing methods. The technology also allows for quick prototyping and testing, which can save time and money in the development process.

Another advantage of 3D printing is that it can produce objects with complex geometries and internal structures that would be difficult to achieve with traditional manufacturing methods. This opens up new possibilities for creating functional, lightweight, and efficient designs in a variety of industries, from aerospace to medical devices.

In addition to its many benefits, 3D printing is also becoming more accessible and affordable. The cost of 3D printers has decreased significantly in recent years, making it possible for individuals and small businesses to purchase and use the technology. Also, the development of open-source software and online communities, such as All3DP.com, has made it easier for people to learn about and experiment with 3D printing.

In conclusion, 3D printing is a powerful and versatile technology that is rapidly changing the way we think about manufacturing. With its ability to produce customized, complex objects in a fraction of the time it would take using traditional methods, 3D printing has the potential to transform the way we design and produce everything from consumer goods to medical devices.

About the author

Nicole Holt is an experienced 3D enthusiast with a career in marketing and content writing. Thanks to this unique combination, she is able to showcase the technical intricacies of 3D art and rendering while also making the subject accessible to a wide audience. When she's not immersed in the digital world, Nicole can be found in the great outdoors, most likely with her beloved dog, Sammy.